Why Choose a Hydraulic Oil Press for Peanut Oil?

The hydraulic oil press machine uses a slow and uniform hydraulic pressing process, which is superior to mechanical screw pressing in terms of oil yield, oil quality and machine lifespan.

Key advantages of hydraulic oil pressing:

- Oil yield up to 55%

- Residual oil as low as 6–8%

- Stable hydraulic system ensures long-term reliability

- No chemical solvents, 100% physical pressing

- Suitable for both hot pressing and cold pressing

As you can see from the picture above, the hydraulic oil press model 325 which has 325 tons down pressure ability is suitable for peanut/groundnut.The pressed cake can be very solid, which means the residual oil rate is very low.

As you can see from the picture above, the hydraulic oil press model 325 which has 325 tons down pressure ability is suitable for peanut/groundnut.The pressed cake can be very solid, which means the residual oil rate is very low.

Compared with traditional screw oil presses and mechanical oil presses, the hydraulic oil press machine offers several advantages for peanut oil production:

- Higher and more stable pressing pressure: The hydraulic system provides consistent pressure throughout the pressing process, ensuring optimal oil extraction from peanuts.

- Lower residual oil content in peanut cake: The high pressure exerted by the hydraulic oil press results in a drier peanut cake with minimal oil content, maximizing oil yield.

- More suitable for high-value edible oil production: The gentle pressing action of the hydraulic oil press helps maintain the nutritional integrity of the peanut oil, making it ideal for premium edible oil products.

Video of Hydraulic Oil Press Working

Technical Parameters of 325 Hydraulic Oil Press machine for Peanut Oil

- Model: 325 hydraulic oil press

- power supply: 3 phase, 380V, 50Hz

- Motor power: 2.2 KW

- Oil cylinder outer diameter: 325 mm,Oil cylinder inner diameter: 260 mm

- Total Pressing Force: 325 tons

- Stroke 850 mm → Minimum single pressing amount: 5 kg

- Equipment weight uses original range, in tons (t):1.4ton

- System pressure: 60 MPa

- Oil cylinder material: 27 Silicon Manganese Steel

- Frame material: H-type channel steel

- Hook quantity: 4

- Barrel material: Carbon steel with nickel plating

- Barrel inner diameter: 390mm

- Barrel height: 800mm

- Hydraulic oil model: No. 46 wear-resistant hydraulic oil press special hydraulic oil

- Hydraulic oil capacity: 90kg

- Maximum feeding capacity: 100 kg crushed peanut powder (one time)

| Item | Specification |

|---|---|

| Model | 325 Hydraulic Oil Press |

| Pressing Force | 325 Tons (Hydraulic) |

| Hydraulic Pressure | 60 MPa |

| Motor Power | 2.2 kW |

| Voltage | 380V / 50Hz / 3 Phase |

| Barrel Size | Ø390 × 800 mm |

| Max Feeding Capacity | 100 kg |

| Equipment Weight | 1.4 tons |

Recommended feeding volume for hydraulic oil press 325

Suggested feeding amount per press: 60 kg

(to save feeding time)If you need to feed 100 kg at one time:

Pre-pressing action is required before the main pressing.

Processing Time for hydraulic oil press 325

- Pre-pressing time: 5-10 minutes

- Main pressing time: 30-40 minutes

- Total time: 35-50 minutes for 100 kg peanut powder

- 1.5 hours for 200 kg peanut powder

Peanut Oil Yield of hydraulic oil press 325

- Oil yield: 45-55% (related to raw material quality)

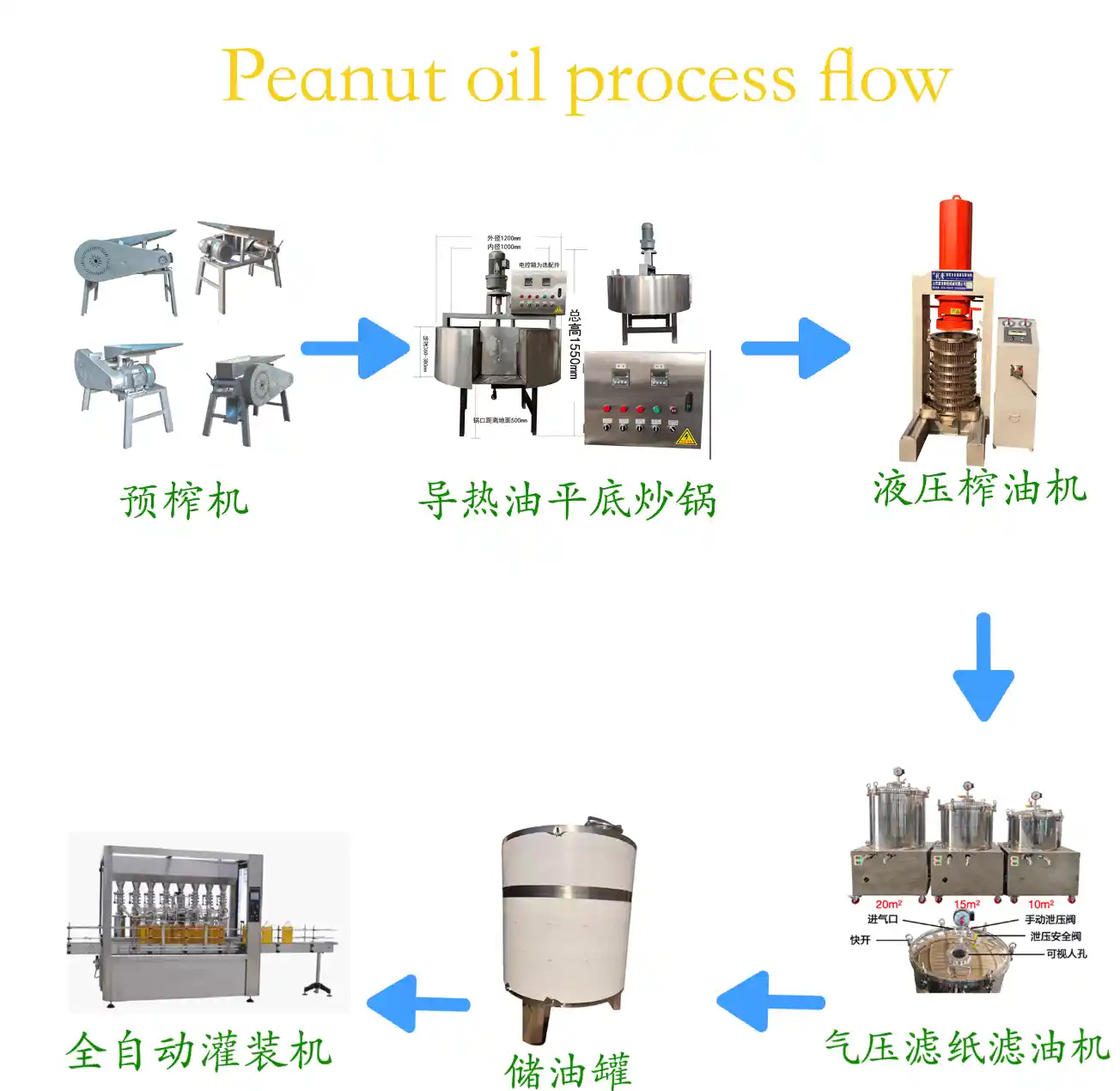

Overview of peanut pressing process using Hydraulic Oil Press

- Crush peanuts into powder with a crusher machine(pre-press machine)

- Roast the peanut powder in a flat-bottomed wok to enhance aroma and oil yield

- Feed the roasted peanut powder into the hydraulic oil press barrel

- Press the oil out of the peanut powder

- Collect the peanut oil and filter it using a pneumatic filter press for clarity and purity.

- Collect the pressed peanut cake for further processing or use, such as pulverizing for additional oil extraction or as animal feed.

- The pressed cake can be further processed using a Cake Pulverizer machine to achieve higher oil extraction rates or can be used as animal feed directly.

- Store the filtered peanut oil in clean, food-grade containers for distribution or further refining if necessary.

- Configure suitable filling equipment according to the production demand, and fill the peanut oil into the bottle.

If your working space is limited

If your working space is limited, we can provide a crushing and stir-frying all-in-one machine, which integrates auto lift-feeding, crushing and roasting, with a small area and easy operation, suitable for small workshops and family workshops. auto lift-feeding, crushing and roasting video attached below:

⚙️ Hydraulic Oil Press machine Core Features

⚙️ Technical Highlights

- High Pressure Stability: Imported hydraulic components, continuous pressure output;

- High Oil Yield: Optimized barrel structure and pressing plate design;

- Quiet Operation: Low noise hydraulic system;

- Energy Saving and Environmental Protection: Low energy consumption, no waste water or gas emissions;

- Easy Operation and Maintenance: Humanized design, convenient cleaning and disassembly.

- Efficient Oil Yield: Adopts optimized piston structure and barrel design, oil yield increased to 48%-55%.

- Pure Physical Pressing: No addition of any chemical solvents, ensuring pure and healthy oil quality.

- Multi-purpose Adaptability: Not only suitable for peanuts, but also for sesame, walnuts, sunflowers and other oil crops.

Customer Service

- ✅ Free sample testing (customers can send raw materials)

- ✅ Technical consultation and project design

- ✅ On-site installation, commissioning and training

- ✅ One-year warranty, lifetime maintenance

- ✅ Customized exclusive production lines and logo identification

Contact Us

If you are interested in peanut pressing solutions, please contact our technical team:

- 📞 Hotline: +86 19906365856

- 📧 Email: gavin@oil-pressing-machine.com

- 📍 Address: No. 5888, Yineng Street, Development Zone, Qingzhou City, Shandong Province, China

We provide free technical consultation, sample testing, and on-site inspection services to provide you with the most suitable peanut pressing solutions.

Other Notes

Our factory specializes in the research, development and production of practical oil refining production line equipment, with scales ranging from small to large, daily production capacity of 1-100 tons can be designed and manufactured. We can provide overall design and professional design for customers, providing users with advanced technology and oil refining equipment at the domestic leading level. We can meet different levels and different requirements of process design and technical services according to user requirements. Our factory is a national key backbone enterprise for oil machinery, specializing in the research and development of oil refining technology.

seo:

title: Hydraulic Oil Press Machine for Peanut Oil Processing | 325 Hydraulic Oil Press Manufacturer

description: High pressure hydraulic oil press machine for peanut and groundnut oil processing. 325 hydraulic oil press offers up to 55% oil yield, low residual oil, stable performance. Factory direct supply.

keywords: hydraulic oil press machine, hydraulic oil press for peanut, hydraulic oil press manufacturer, peanut hydraulic oil press, groundnut hydraulic oil press, high pressure oil press machine, industrial hydraulic oil press