Series Overview

The 355 Series Hydraulic Oil Press is our classic model, suitable for small and medium-sized oil mills. This series features compact structure, simple operation, and stable performance.

It mainly consists of frame, hydraulic cylinder, and material barrel. The control box uses a microcomputer controller, all programs are software connected, and the control program will not be damaged.

The 355 model is suitable for hot pressing: sesame, tea seed, walnut, peanut, soybean, flax, rapeseed, sunflower seed, oil sludge, oil residue, meal, waste clay, animal oil residue, medicinal residue dehydration.

Dual barrel dual sliding track design - when one barrel is pressing, it does not affect the other barrel loading, greatly improving work efficiency.

Product Parameters

355 Model Hydraulic Oil Press Parameter Table

355 Model Hydraulic Oil Press —— Consolidated Parameter Table

Instructions

- Total Pressing Force: 370 tons

- Stroke 850 mm → Minimum single pressing amount: 5 kg

- Stroke 700 mm → Minimum single pressing amount: 40 kg

- System pressure uniformly marked as 60 MPa

- Equipment weight uses original range, in tons (t)

355AC —— Single Barrel Type

| Barrel Diameter (mm) | Height (mm) | Volume (L) | Stroke (mm) | Minimum Single Pressing Amount (kg) | Main Dimensions W×L×H (mm) | System Pressure (MPa) | Cake Surface Pressure (MPa/cm²) | Equipment Weight (t) |

|---|---|---|---|---|---|---|---|---|

| 300 | 800 | 57 | 850 | 5 | 720×1050×2450 | 60 | 52 | 1.8–1.9 |

| 390 | 800 | 96 | 850 | 5 | 800×1100×2450 | 60 | 31 | 1.8–1.9 |

| 480 | 800 | 145 | 850 | 5 | 900×1300×2450 | 60 | 20 | 1.8–1.9 |

| 560 | 800 | 197 | 850 | 5 | 1000×1400×2450 | 60 | 15 | 1.9–2.0 |

| 630 | 800 | 249 | 850 | 5 | 1100×1600×2450 | 60 | 12 | 1.9–2.0 |

| 300 | 800 | 57 | 700 | 40 | 720×1050×2450 | 60 | 52 | 1.8–1.9 |

| 390 | 800 | 96 | 700 | 40 | 800×1100×2450 | 60 | 31 | 1.8–1.9 |

| 480 | 800 | 145 | 700 | 40 | 900×1300×2450 | 60 | 20 | 1.8–1.9 |

| 560 | 800 | 197 | 700 | 40 | 1000×1400×2450 | 60 | 15 | 1.9–2.0 |

| 630 | 800 | 249 | 700 | 40 | 1100×1600×2450 | 60 | 12 | 1.9–2.0 |

355BC —— Dual Barrel Type (Two identical barrels, total volume = single barrel × 2)

| Barrel Diameter (mm) | Height (mm) | Total Volume (L) | Stroke (mm) | Minimum Single Pressing Amount (kg) | Main Dimensions W×L×H (mm) | System Pressure (MPa) | Cake Surface Pressure (MPa/cm²) | Equipment Weight (t) |

|---|---|---|---|---|---|---|---|---|

| 300 | 800 | 114 | 850 | 5 | 720×1100×2450 | 60 | 52 | 2.1–2.2 |

| 390 | 800 | 192 | 850 | 5 | 800×1150×2450 | 60 | 31 | 2.1–2.2 |

| 300 | 800 | 114 | 700 | 40 | 720×1100×2450 | 60 | 52 | 2.1–2.2 |

| 390 | 800 | 192 | 700 | 40 | 800×1150×2450 | 60 | 31 | 2.1–2.2 |

355AS —— Large-Small Mother-Son Barrel Type (Large barrel + small barrel, total volume = sum of both)

| Large Barrel Diameter (mm) | Small Barrel Diameter (mm) | Height (mm) | Total Volume (L) | Stroke (mm) | Minimum Single Pressing Amount (kg) | Main Dimensions W×L×H (mm) | System Pressure (MPa) | Large/Small Barrel Cake Surface Pressure (MPa/cm²) | Equipment Weight (t) |

|---|---|---|---|---|---|---|---|---|---|

| 390 | 300 | 785 | 149.0 | 850 | 5 | 800×1150×2450 | 60 | 31 / 52 | 2.1–2.2 |

| 390 | 300 | 785 | 149.0 | 700 | 40 | 800×1150×2450 | 60 | 31 / 52 | 2.1–2.2 |

Reference Table for Oil Yield Rates of Various Raw Materials

(Based on 100 kg of raw material)

| Serial No. | Material | Process | Oil Yield (kg) | Percentage (%) |

|---|---|---|---|---|

| 1 | Peanut | Hot Pressing | 42–52 | 42%–52% |

| 2 | Sesame | Hot Pressing | 42–52 | 42%–52% |

| 3 | Tea Seed | Hot Pressing | 15–35 | 15%–35% |

| 4 | Walnut | Cold Pressing | 56–72 | 56%–72% |

| 5 | Soybean | Hot Pressing | 12–18 | 12%–18% |

| 6 | Soybean | Cold Pressing | 12–18 | 12%–18% |

| 7 | Flax / Flaxseed | Hot Pressing | 35–40 | 35%–40% |

| 8 | Flax / Flaxseed | Cold Pressing | 35–40 | 35%–40% |

| 9 | Rapeseed | Hot Pressing | 30–40 | 30%–40% |

| 10 | Rapeseed | Cold Pressing | 30–40 | 30%–40% |

| 11 | Sunflower Seed | Hot Pressing | 45–60 | 45%–60% |

| 12 | Oil Sludge | Hot Pressing | 20–60 | 20%–60% |

| 13 | Oil Sludge | Cold Pressing | 20–60 | 20%–60% |

| 16 | Meal Residue | Hot Pressing | 30–50 | 30%–50% |

| 18 | Waste Clay | Hot Pressing | 8–60 | 8%–60% |

| 19 | Waste Clay | Cold Pressing | 8–60 | 8%–60% |

| 20 | Animal Oil Residue | Hot Pressing | 40–60 | 40%–60% |

| 21 | Animal Oil Residue | Cold Pressing | 40–60 | 40%–60% |

| 22 | Medicinal Residue | Cold Pressing | Weight Loss 70% | Weight Loss 70% |

| 26 | Perilla Seed | Hot Pressing | 30–40 | 30%–40% |

| 27 | Perilla Seed | Cold Pressing | 30–40 | 30%–40% |

| 28 | Coconut Pulp | Cold Pressing | 30–40 | 30%–40% |

| 29 | Palm Fruit | Hot Pressing | Approx. 40 (Estimated) | Approx. 40% (Estimated) |

| 30 | Almond / Apricot Kernel | Cold Pressing | 50–70 | 50%–70% |

| 31 | Hazelnut | Cold Pressing | 50–70 | 50%–70% |

| 32 | Cashew Shell | Hot Pressing | 20–30 | 20%–30% |

| 33 | Cashew Kernel | Cold Pressing | 40–50 | 40%–50% |

| 34 | Grape Seed | Hot Pressing | 10–15 | 10%–15% |

| 35 | Pumpkin Seed | Cold Pressing | 50–70 | 50%–70% |

| 36 | Peach Kernel | Cold Pressing | 50–70 | 50%–70% |

| 38 | Glutinous Rice | Cold Pressing | 20–30 | 20%–30% |

| 39 | Millet Germ | Cold Pressing | 40–50 | 40%–50% |

| 40 | Wheat Germ | Cold Pressing | 40–50 | 40%–50% |

| 41 | Corn Germ | Hot Pressing | 30–45 | 30%–45% |

| 42 | Castor Seed | Hot Pressing | 40–60 | 40%–60% |

Note: The above data are reference values from laboratory or actual production. Different regions' raw material oil content, moisture content, processing temperature, and equipment model factors may cause actual oil yield to vary. Data is for reference only, actual results should be based on actual production.

Pressing Barrel Selection Guide:

- Standard barrel specifications:

- Diameter: 390mm

- Length: 800mm

- Volume: 95.6 liters (can hold about 100kg of crushed material, continuously compacted)

- Can press all oil materials

- 355mm diameter is recommended as sesame-specific barrel

Suitable for sesame and other small particle oil materials

Improve oil yield and efficiency

Volume: 56 liters

- 480mm /560mm /630mm diameter is recommended for oil materials requiring long pressing time

Suitable for oil materials requiring long pressing time

Further improve oil yield and efficiency

Volume: 145/197/249 liters

- Optional 2100 mm length dual barrel model available, mainstream model is 1200 mm length single barrel model

Pressing Material Guide:

- Partial oil material pressing process guidance as follows:

- Peanut (Recommended 355AC-390)

- Peanut oil (rich aroma type) hot pressing process: Crush peanuts - Flat bottom wok roast peanut kernels - Continuously press in hydraulic oil press barrel

- Peanut oil pressed using this process has rich aroma, golden transparency, good taste, pressed oil does not require hydration treatment, no foaming when cooking.

- Basically no filtration treatment needed, settling and bottling directly. COFCO Group high-end peanut oil uses pressing process (crushing, roasting, pressing, filtering equipment provided by our factory).

- Sesame (Recommended 355AC-390)

- Sesame oil hot pressing process: Drum roaster roast sesame - Direct barrel pressing. Sesame oil pressed using this process has rich aroma, sweet aftertaste, pressed oil does not require hydration treatment, no foaming when cooking.

- Basically no filtration treatment needed, settling and bottling directly.

- Tea seed (Recommended 355AC-390)

- Tea seed oil hot pressing process: Tea seeds go through screening, cleaning, drying, crushing, steaming and stir-frying, then connected to hydraulic oil press barrel pressing.

- Tea seed oil pressed using this process has clear color, pure aroma, and rich nutrition.

- Walnut (Recommended 355AC-390)

- Cold pressing process: Walnuts go through screening, cleaning, high-speed crushing, then directly into hydraulic oil press barrel pressing.

- Walnut oil pressed using this process has golden color, sweet aftertaste, pressed oil does not require hydration treatment, no foaming when cooking.

- Soybean (Recommended 300AC-390/325AC-390/350AC-390/400AC-390)

- Cold pressing process: High-speed crushing of soybeans followed by pressing

- Hot pressing process: Soybeans ground into embryo state (crushed) - steamed - pressed

- Flax/Flaxseed (Recommended 355AC-390)

- Flax/Flaxseed hot pressing process: Flax seeds go through heating and stir-frying + grinding and stir-frying, then placed into hydraulic oil press barrel pressing.

- Flaxseed oil hot pressing process: Flax seeds go through high-speed crusher crushing, then placed into hydraulic oil press barrel pressing. Sweet aftertaste, sweet flavor, pressed oil does not require hydration treatment, no foaming when cooking.

- Rapeseed (Recommended 355AC-390)

- Rapeseed oil hot pressing process: Rapeseeds go through cleaning, crushing, stir-frying and steaming processes, then placed into hydraulic oil press barrel pressing.

- Rapeseed oil pressed using this process has high oil yield, golden color, and fragrant taste.

- Sunflower seed (Recommended 355AC-390) + Sunflower seed oil hot pressing process: Sunflower seeds go through cleaning, crushing, and stir-frying processes, then placed into hydraulic oil press barrel pressing.

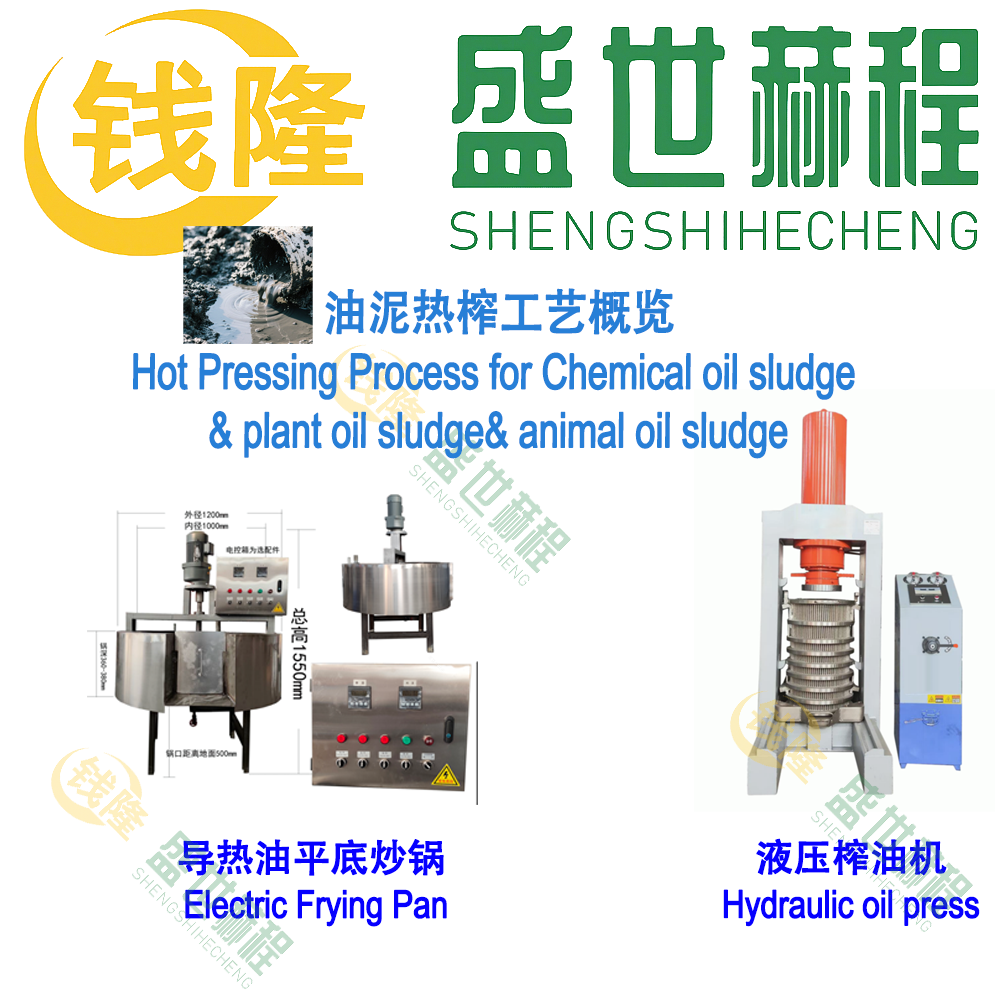

- Oil sludge (Recommended 355AC-390)

- Oil sludge hot pressing process: Oil sludge goes through high-temperature stir-frying process, then placed into hydraulic oil press barrel pressing.

- Oil residue (Recommended 355AC-390)

- Oil residue hot pressing process: Oil residue goes through high-temperature stir-frying process, then placed into hydraulic oil press barrel pressing.

- Oil residue cold/hot pressing process: Directly placed into hydraulic oil press barrel pressing.

- Meal residue (Recommended 355AC-390)

- Meal residue hot pressing process: Meal residue goes through high-temperature stir-frying process, then placed into hydraulic oil press barrel pressing.

- Oil residue cold/hot pressing process: Directly placed into hydraulic oil press barrel pressing.

- Waste clay (Recommended 355AC-390)

- Waste clay cold/hot pressing process: High-temperature steaming, then directly placed into hydraulic oil press barrel pressing.

- Waste clay cold pressing process: Directly placed into hydraulic oil press barrel pressing.

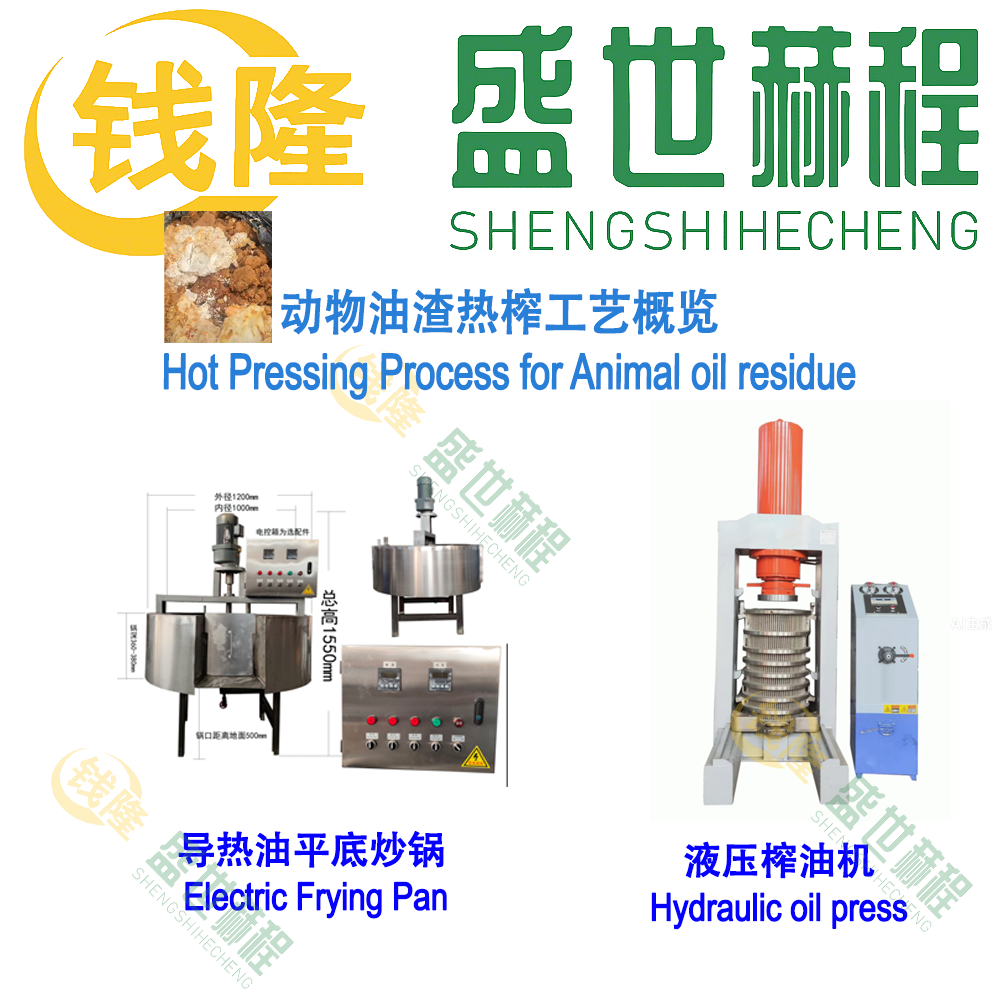

- Animal oil residue (Recommended 355AC-390)

- Animal oil residue hot pressing process: High-temperature stir-frying, then directly placed into hydraulic oil press barrel pressing.

- Animal oil residue cold pressing process: Directly placed into hydraulic oil press barrel pressing.

- Medicinal residue (Recommended 355AC-390)

- Peanut (Recommended 355AC-390)

Model Series

355 Model Series

355 Model Coconut Juice Press (Food Grade Stainless Steel)

- Made of 304 food grade stainless steel

- Specially designed for coconut pressing

- Sanitary grade sealing system

- Suitable for beverage processing enterprises

General Technical Parameters

Standard Configuration

- Main machine

- Control system

- Feeding device

- Discharge system

- Basic tool set

Optional Configuration

- Automatic feeding system

- Pre-auxiliary processing equipment

- Post-filtration processing equipment

Core Advantages

Production Efficiency

- High capacity design

- Continuous operation capability

- High automation level

Oil Quality

- Precise pressure control

- Intelligent temperature regulation

- Multi-stage filtration system

Operating Costs

- Energy consumption optimized design

- Low maintenance costs

- Reduced labor requirements

After-sales Service

- Standard one-year warranty

- Lifetime technical support

- Regular maintenance service

- Priority spare parts supply

- Technical training support

Product Features

- High-quality steel materials ensure equipment durability

- Intelligent pressure control system ensures optimal oil yield

- High automation level reduces manual operation

- Simple maintenance, low operating costs

Product Gallery

355 Series Oil Press - Front View

355 Series Oil Press - Side View

355 Series Oil Press - Control Panel

355 Series Oil Press - Detail View

Application Range

- Small oil mills

- Family workshops

- Rural cooperatives

- Demonstration factories

Supporting Services

- Free installation and commissioning

- Operator training

- Lifetime technical support

- Regular maintenance